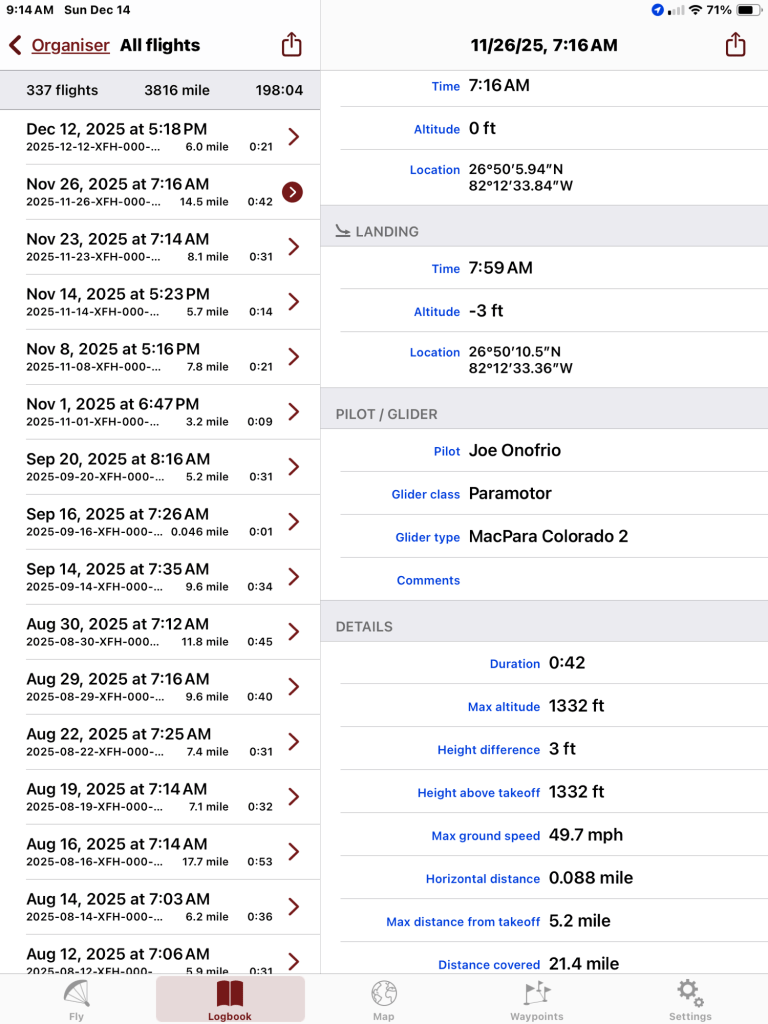

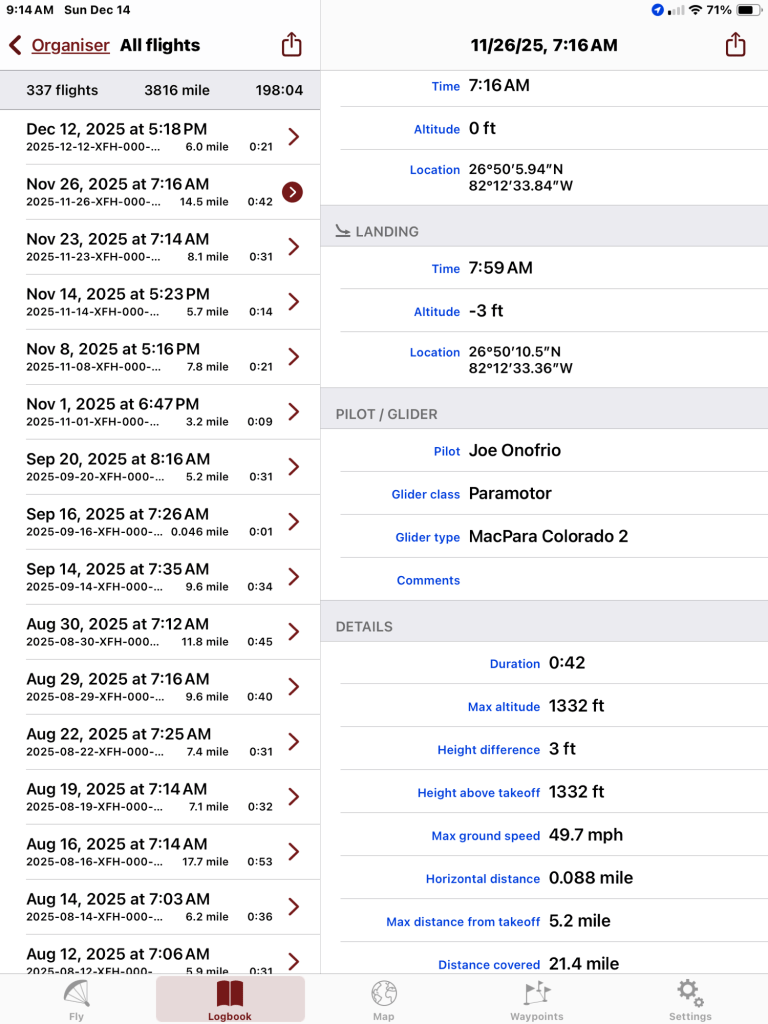

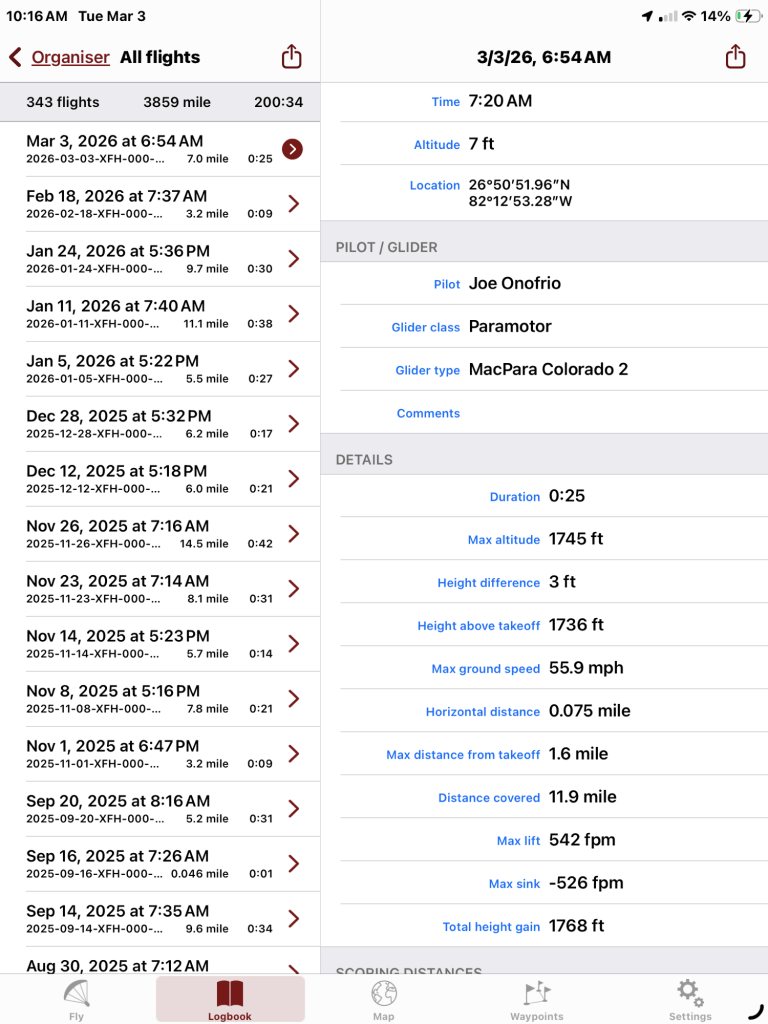

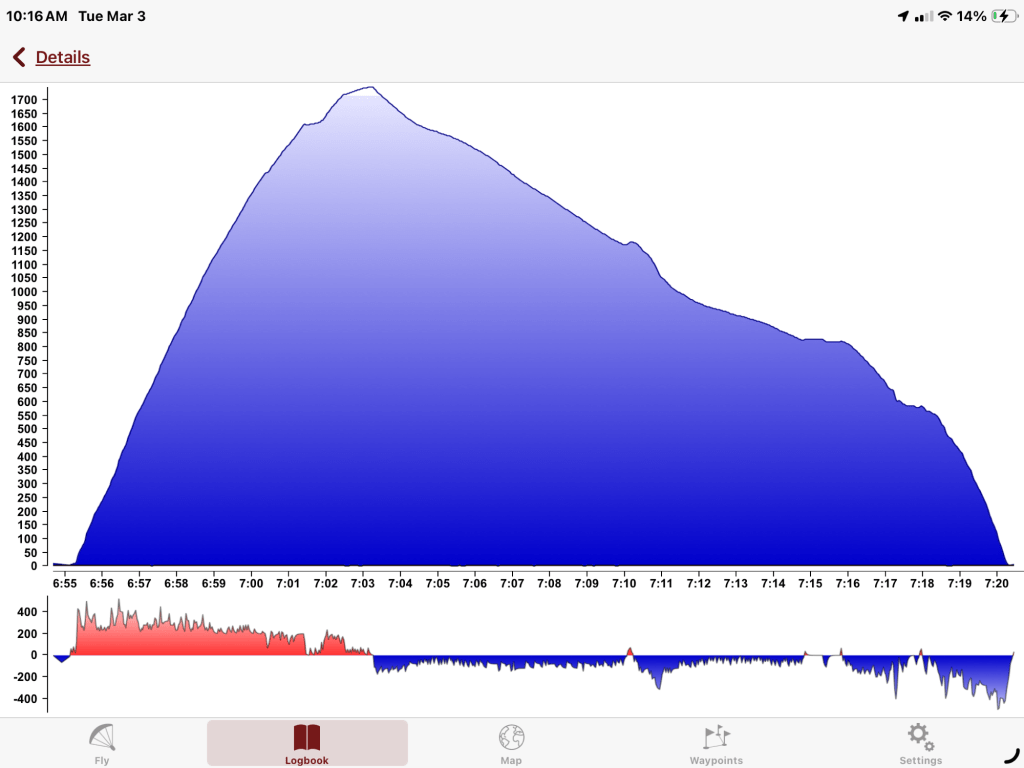

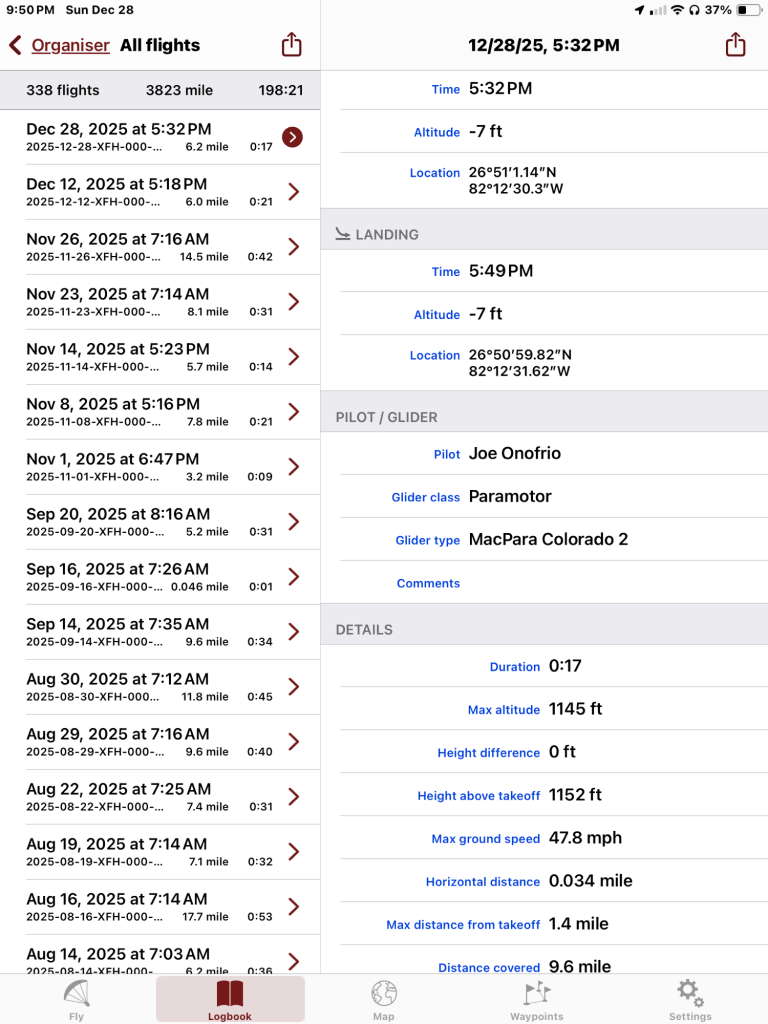

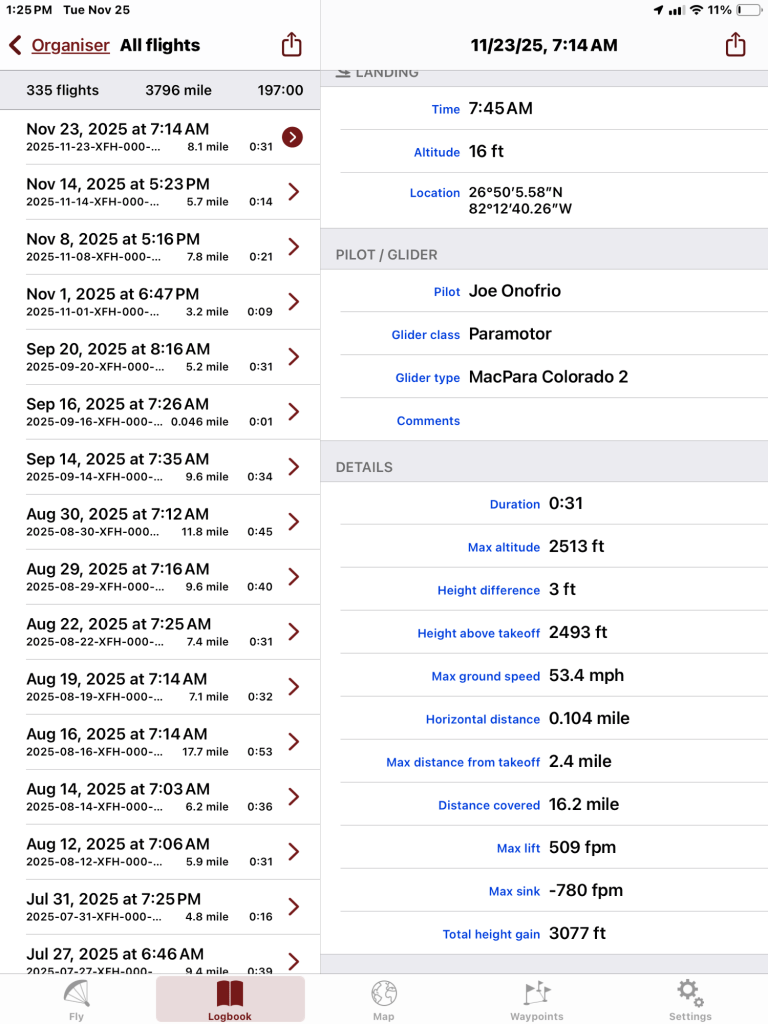

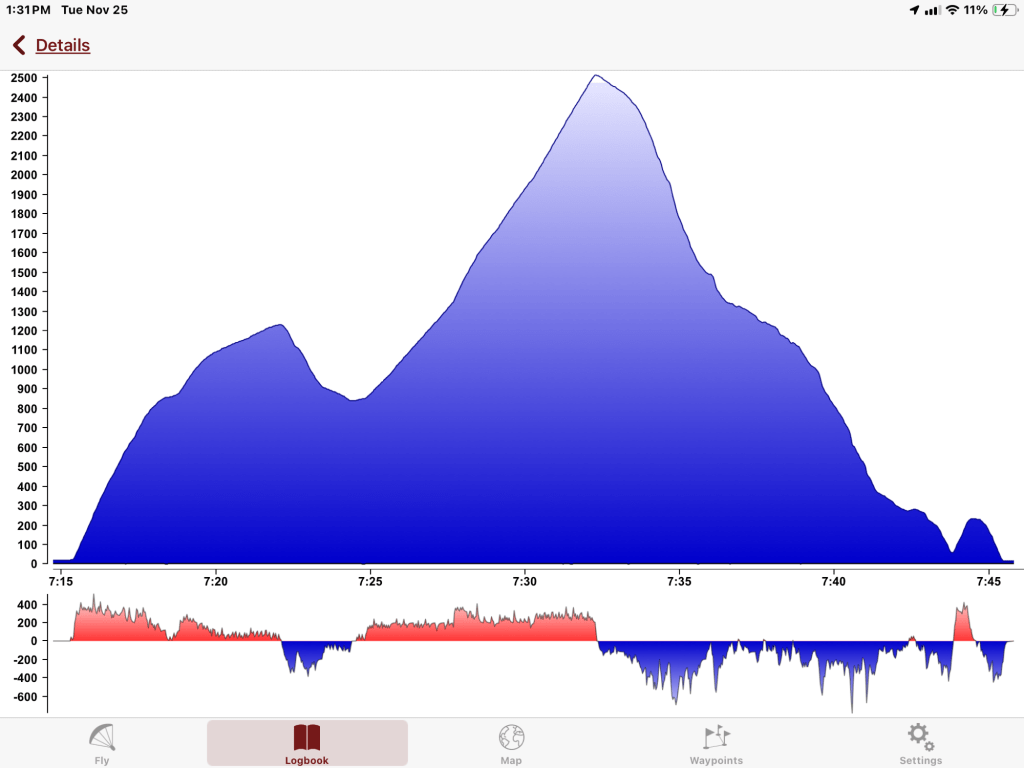

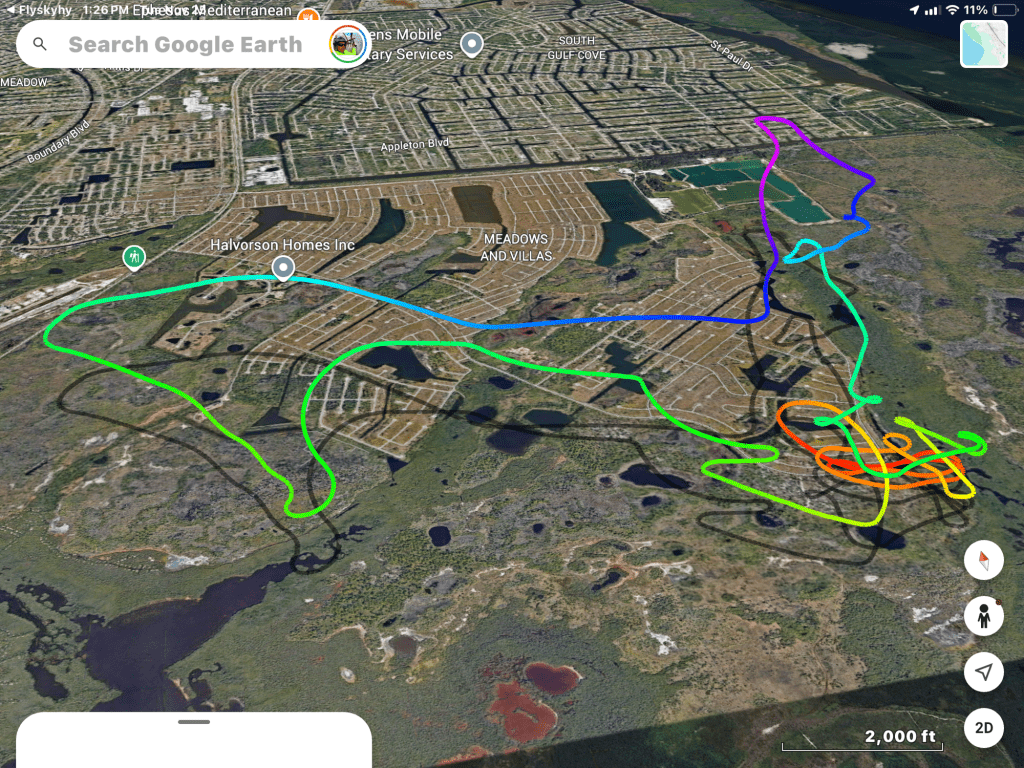

Flight # 1304

Flight # 1304

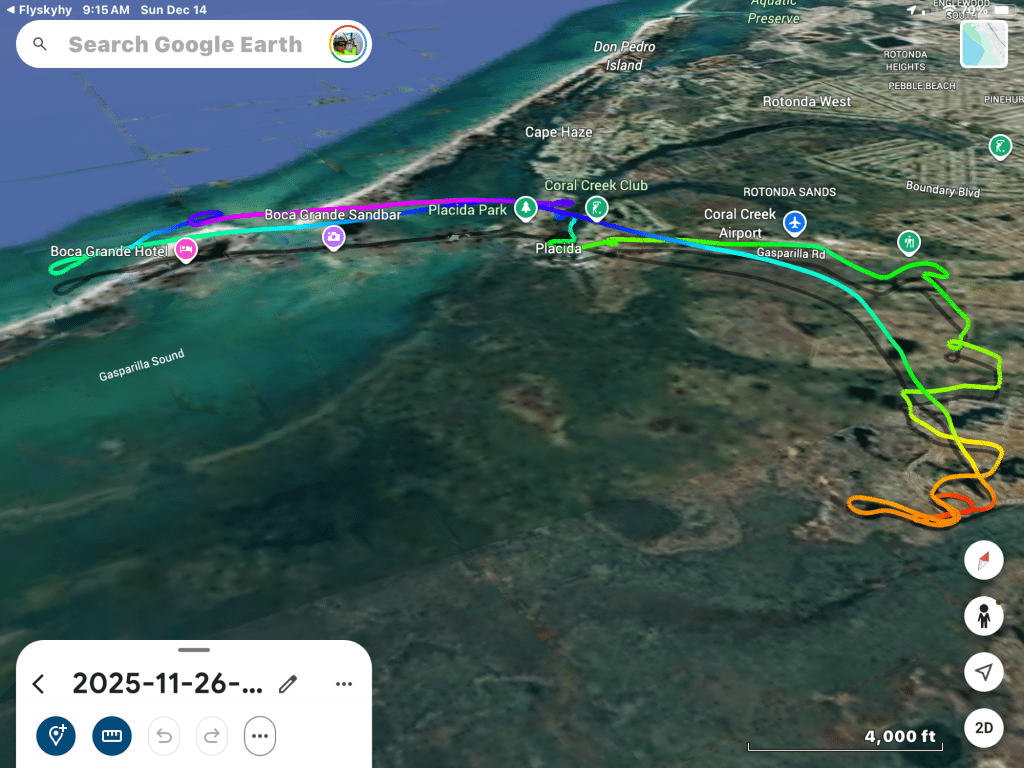

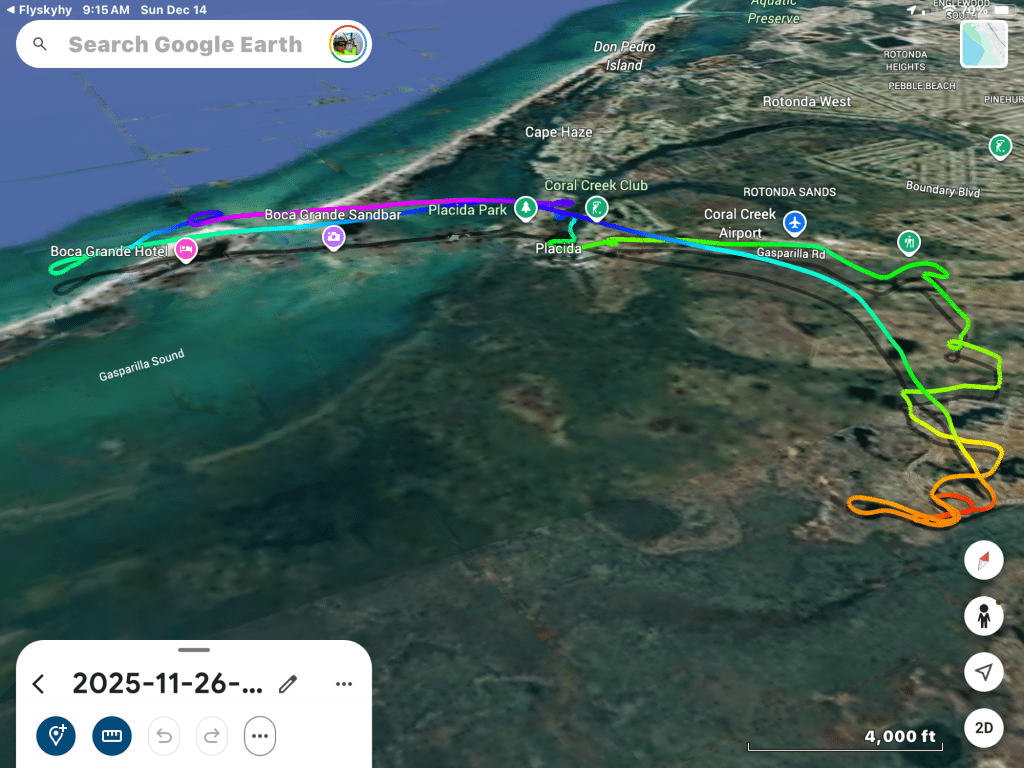

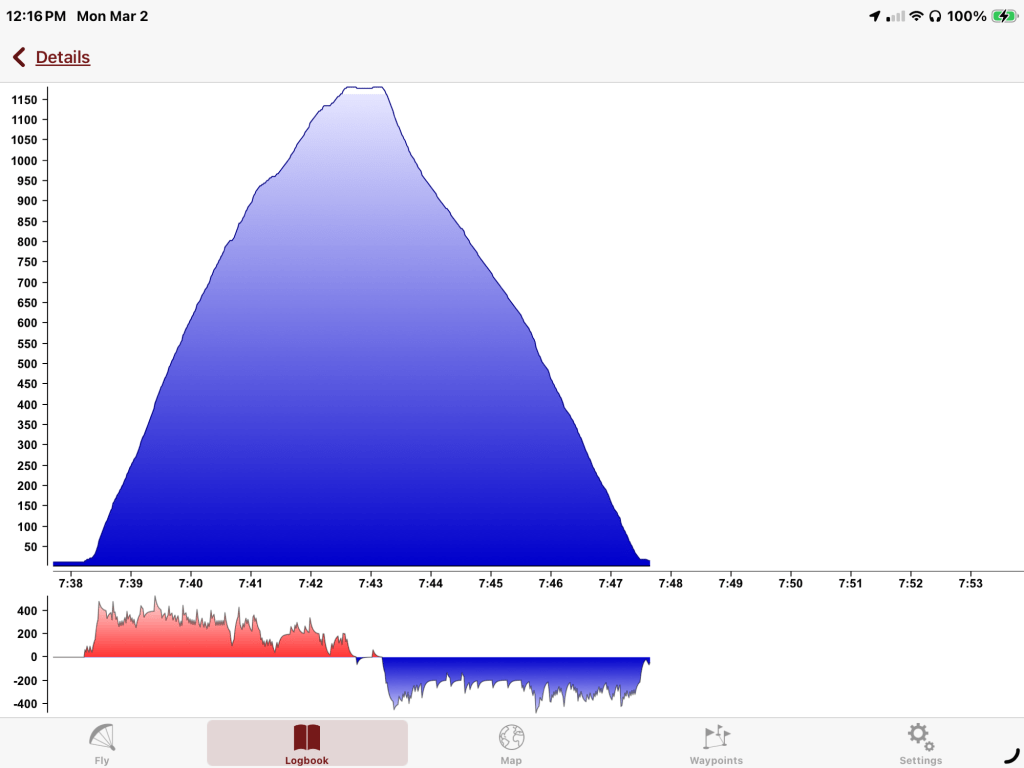

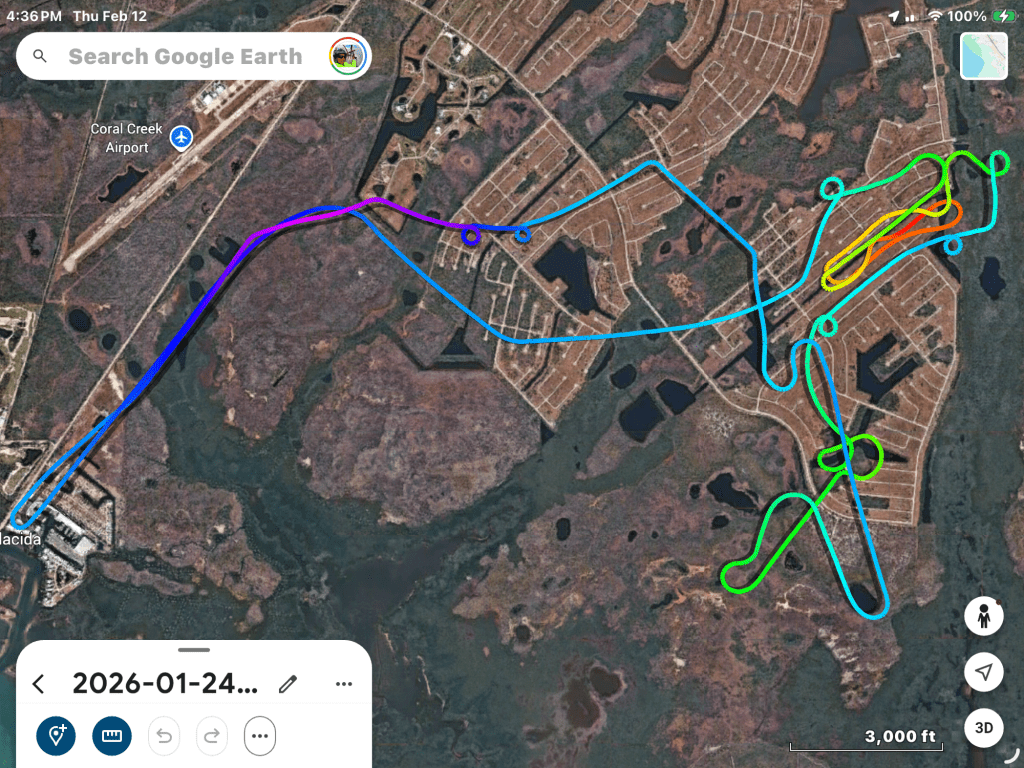

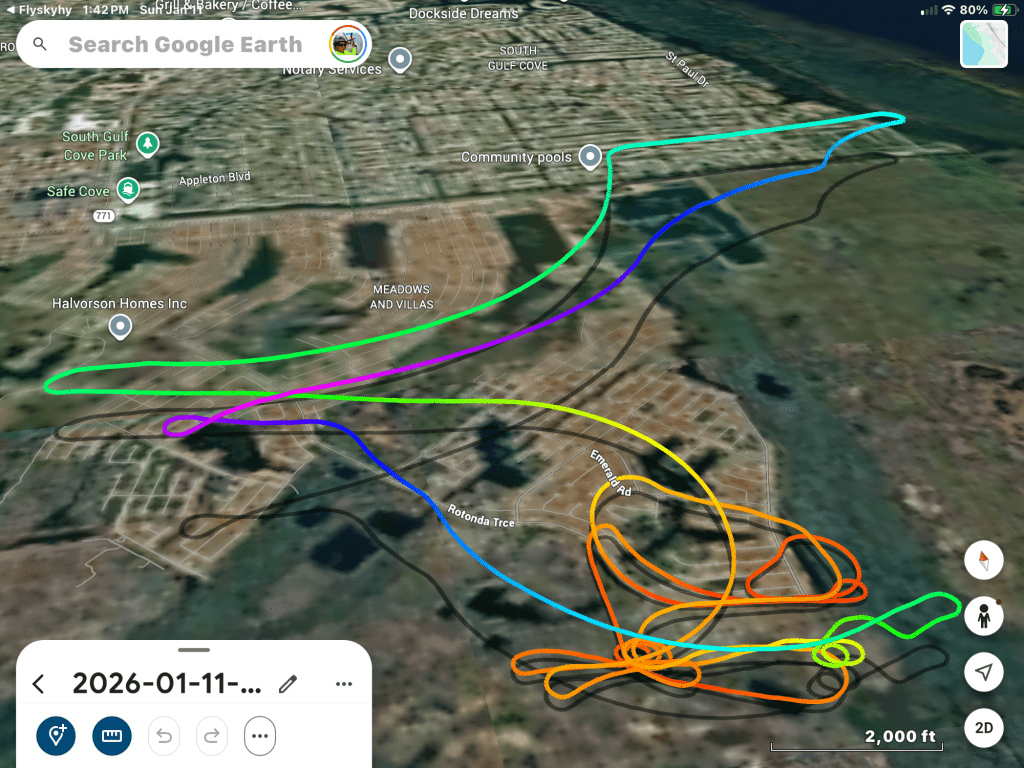

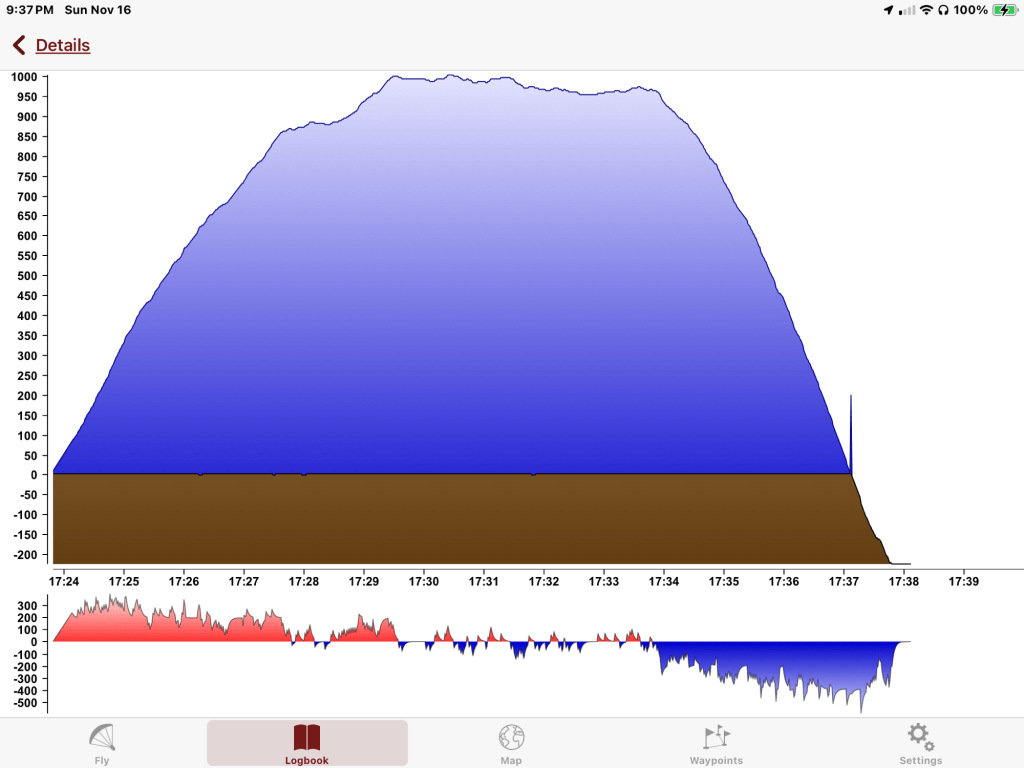

Full lunar eclipse this morning winds were 7 mph and building through the flight.

Short but sweet

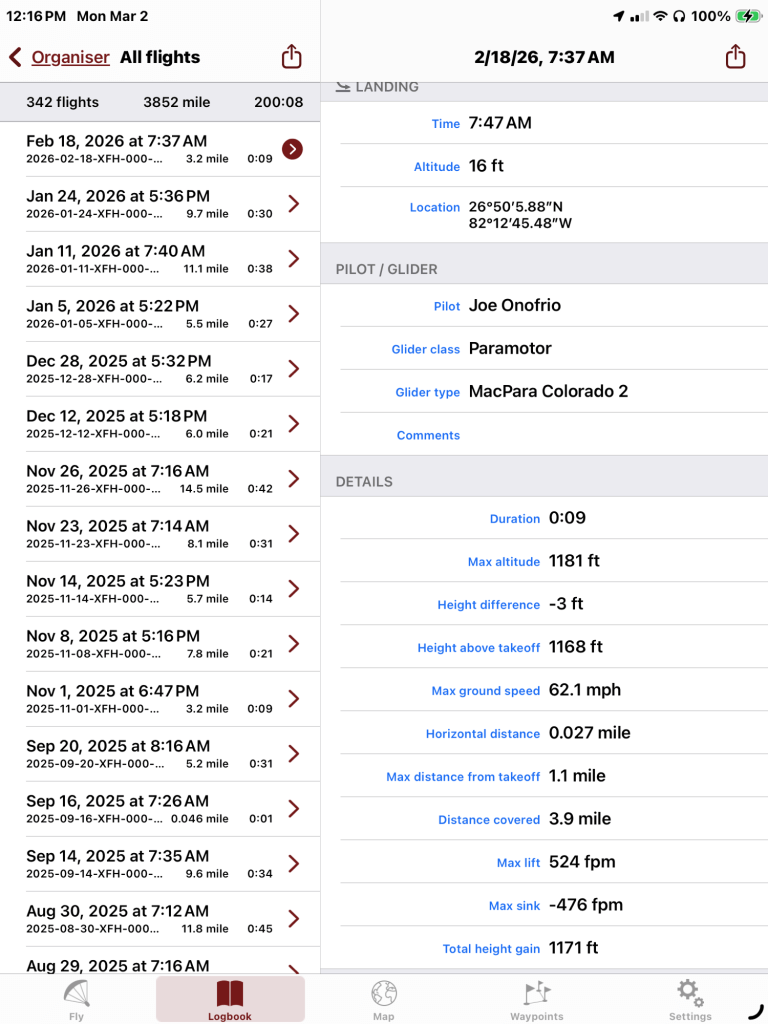

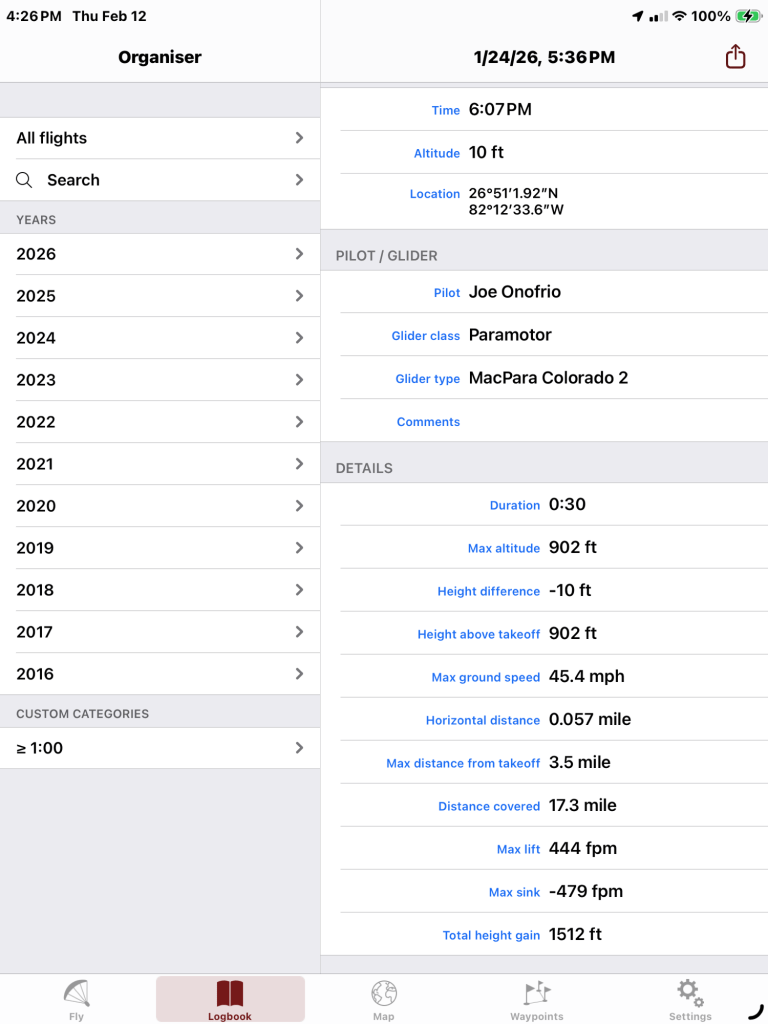

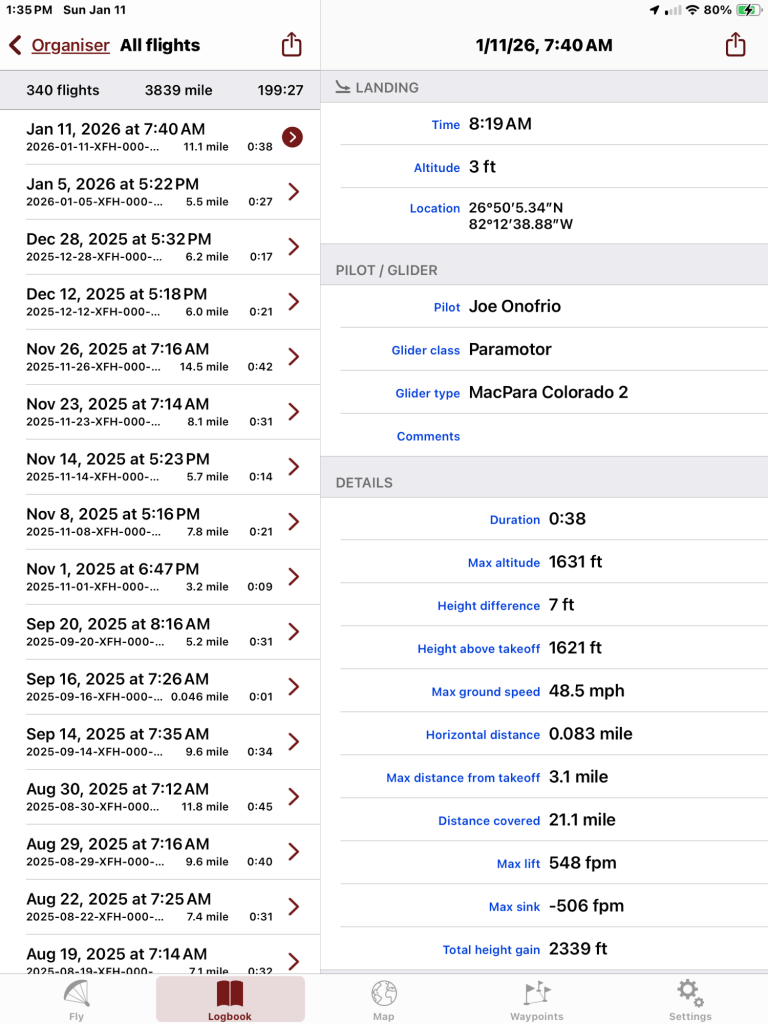

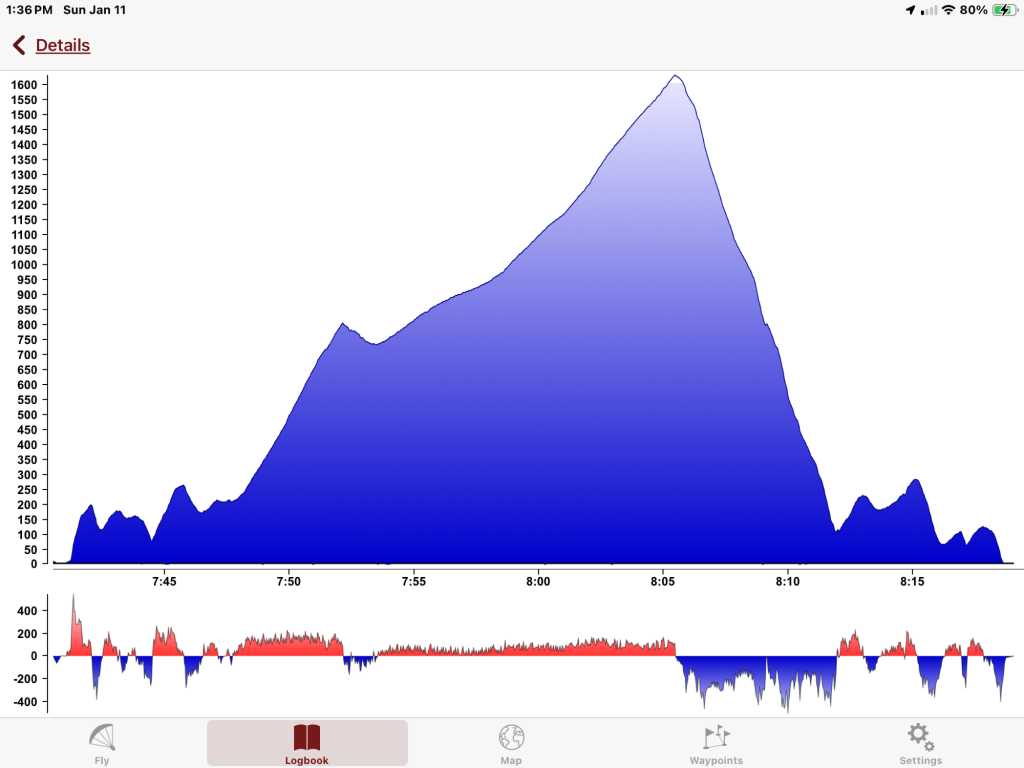

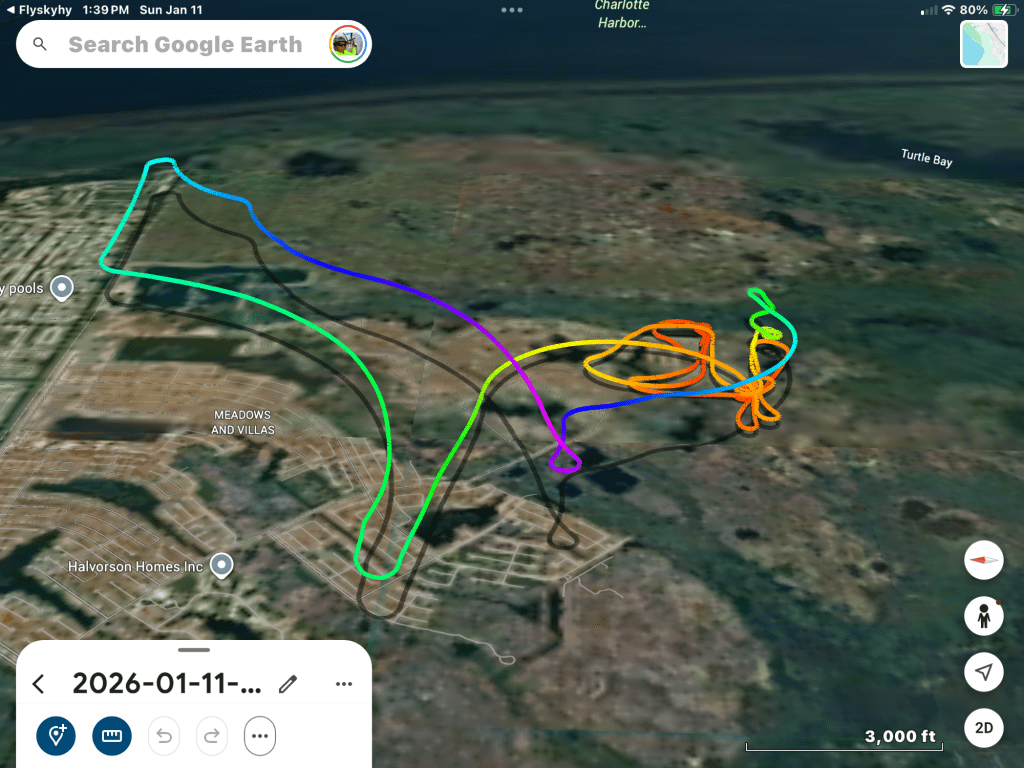

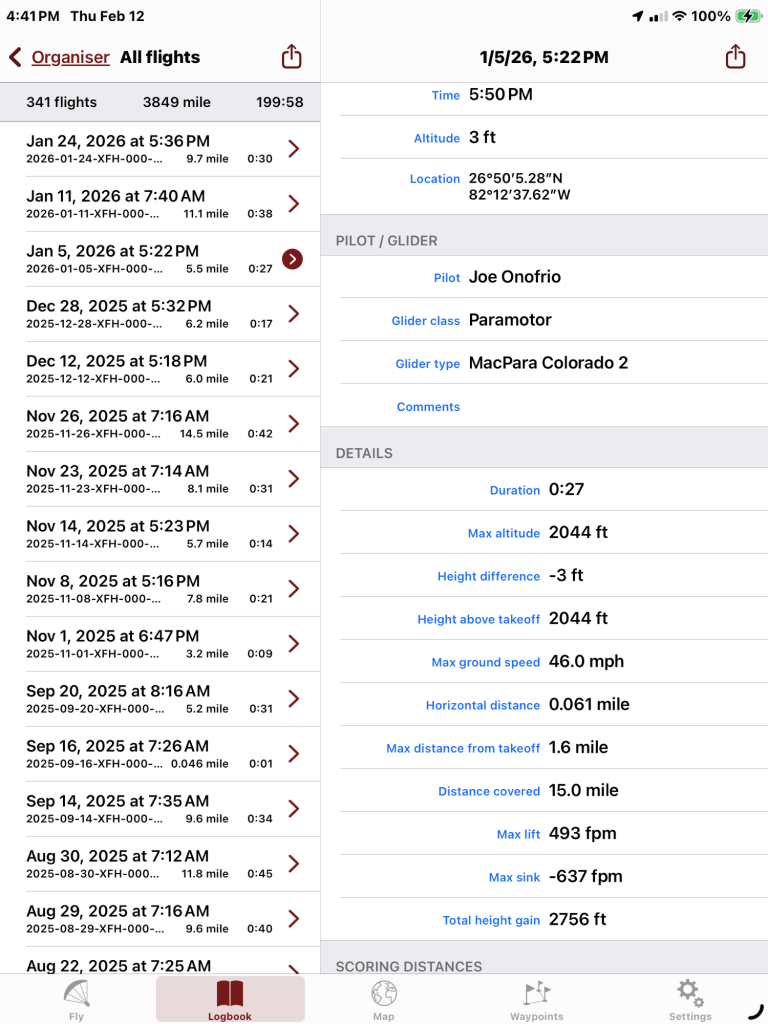

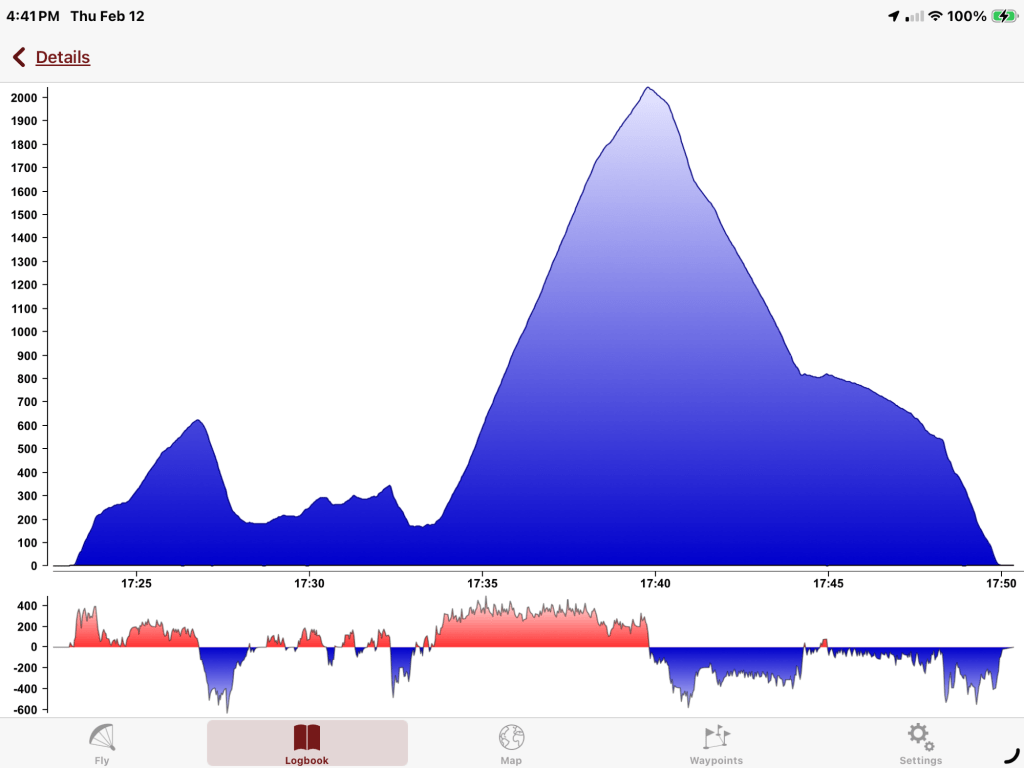

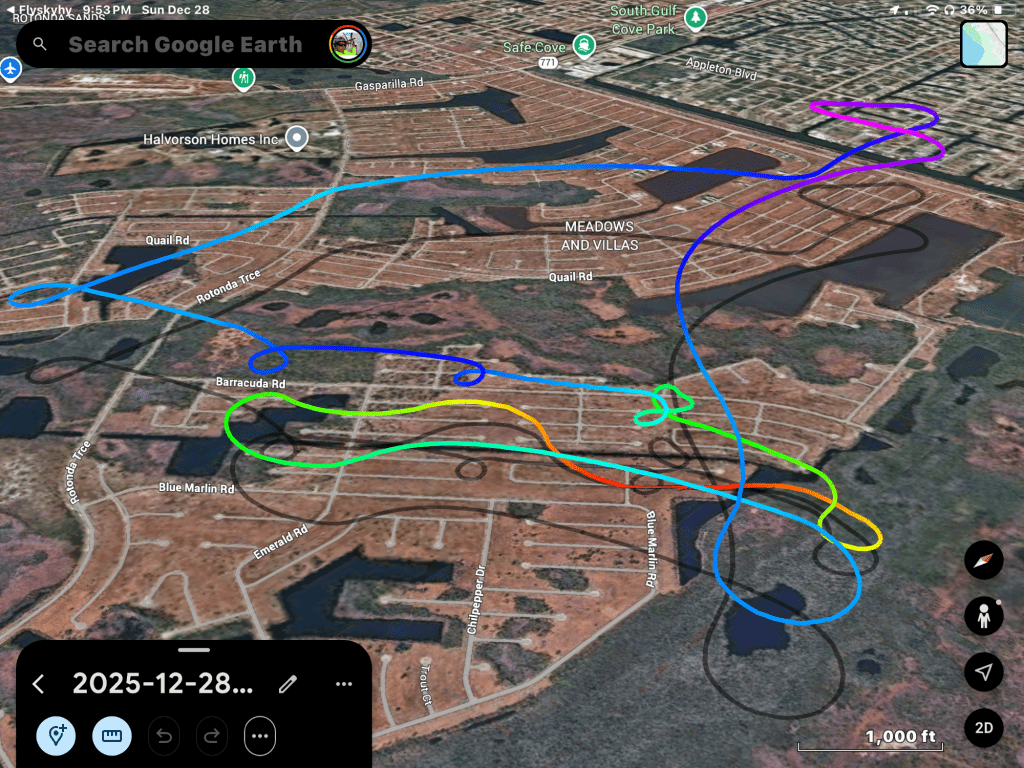

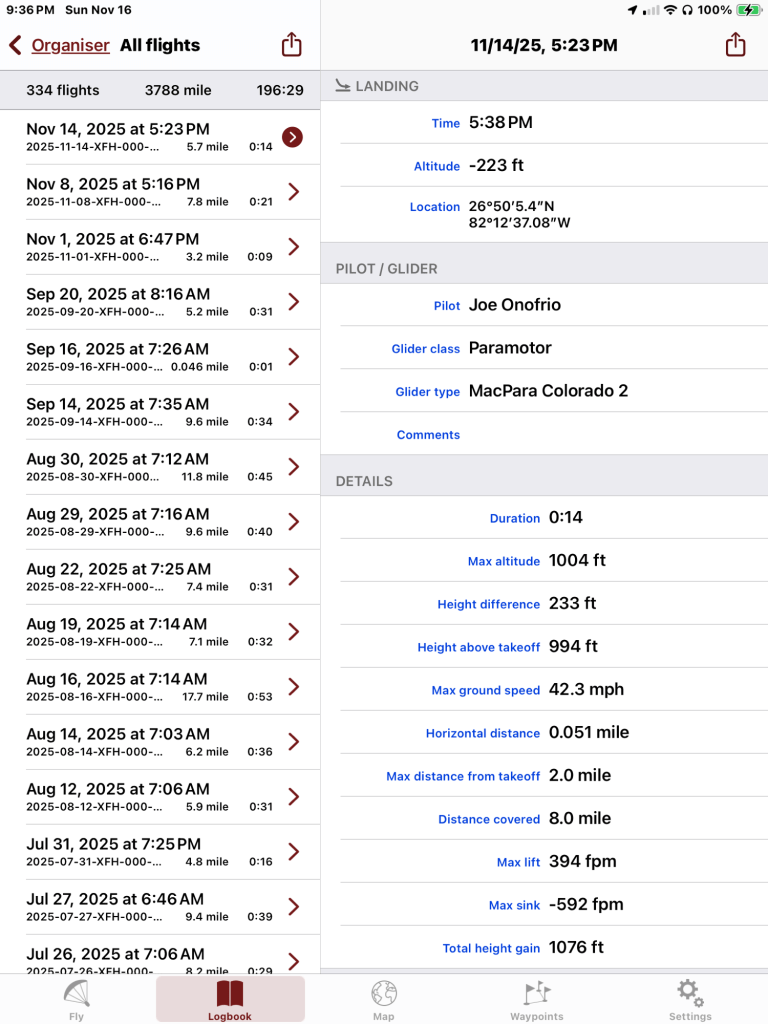

Excellent flight! I raised the risers about 4 inches. The hang points are now above the power loops. Resulting in much better control and comfort.

Starting to get the Colorado 2 dialed in.

Raising the angle of the prop wash and increasing the angle of the “chevron” has greatly improved inflation.

The wing behaved well while I was getting “in” to the risers and inflated clean. The center (leading edge)still looks like it’s wants to frontal but as soon as I’m rolling it comes up and catches the wind.

Notables:

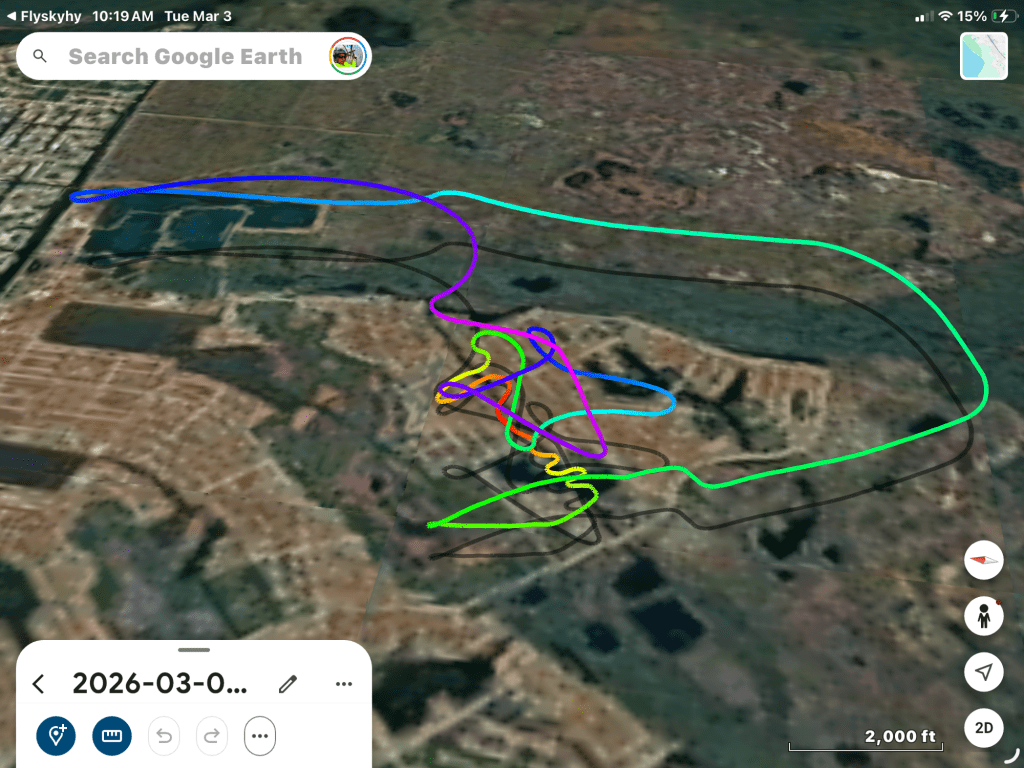

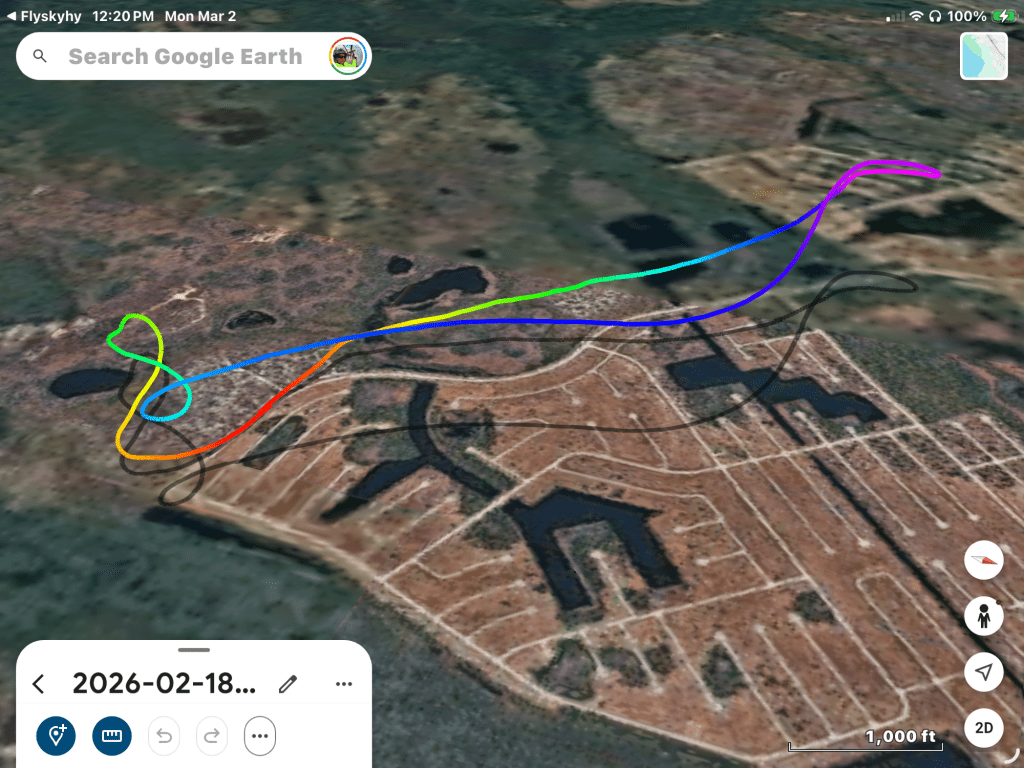

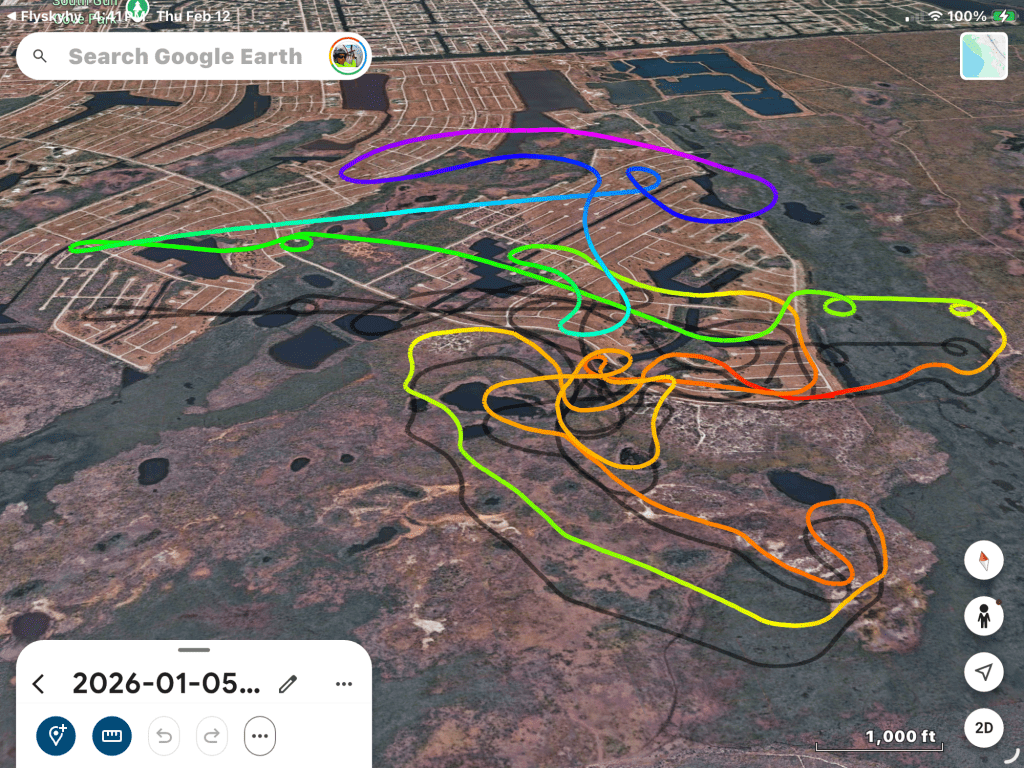

There is a group of Pink Flamingos hanging with white egrets in a pond a the South end of the preserve.

The 2d steering works poorly when putting the brakes away from the body but well on the close and down I put.

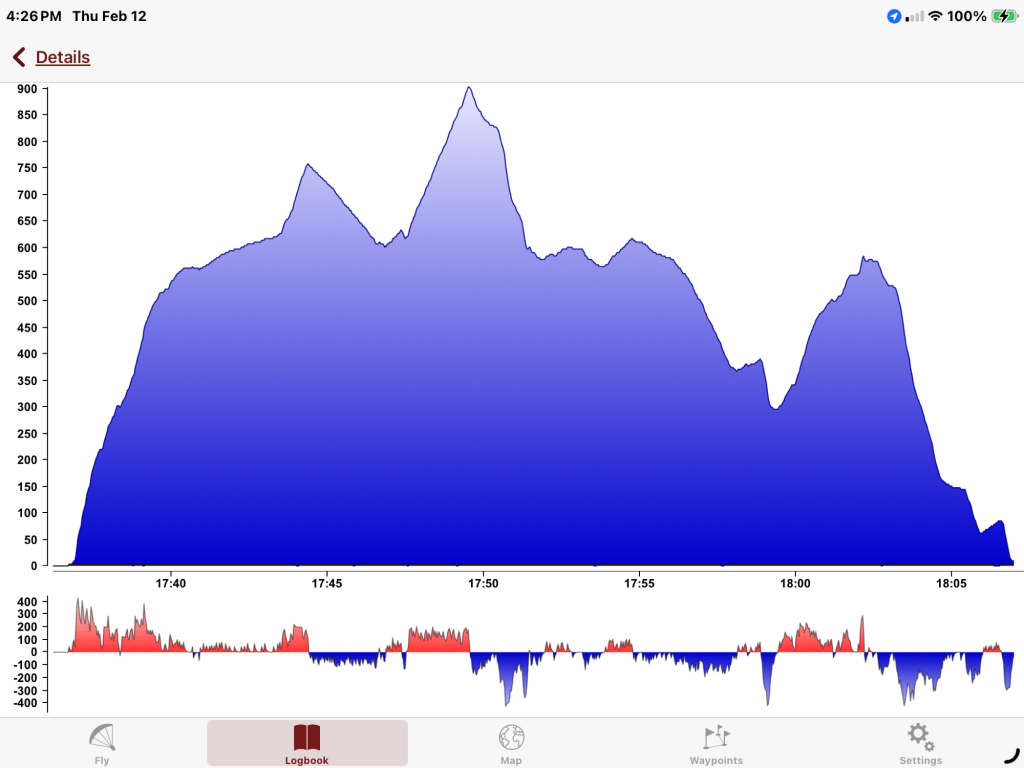

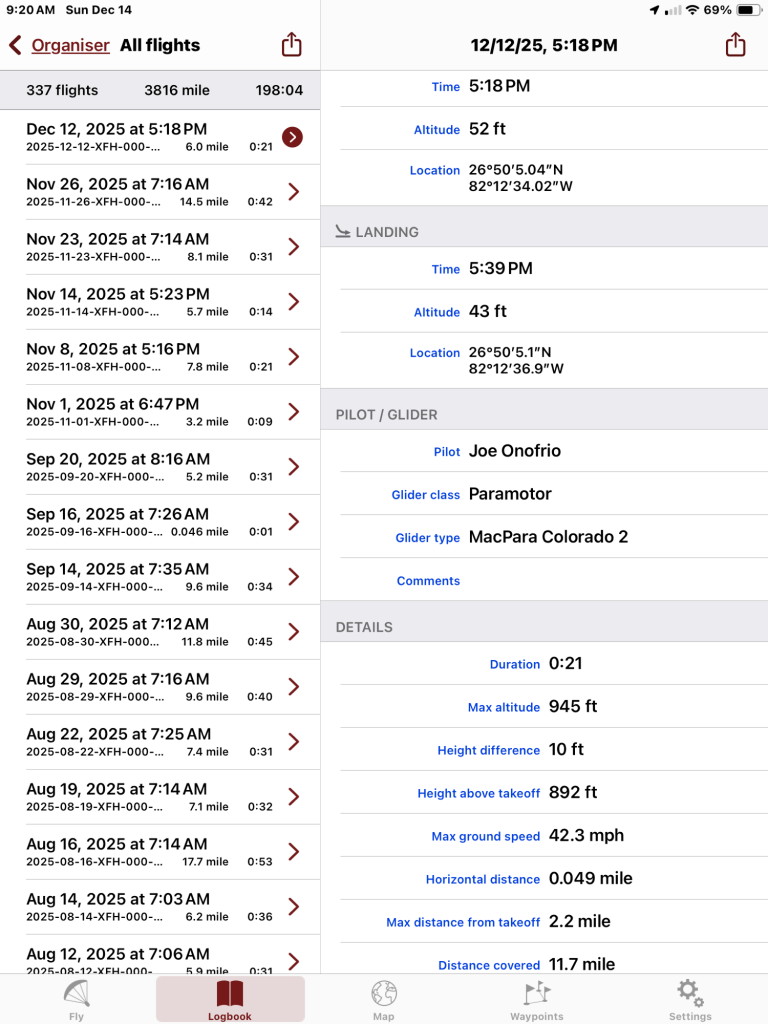

It was a challenging afternoon that culminated with a hard landing . I did a bit of kiting while the winds settled down. It was variable 5 to 10 cycling about every few minutes. The good news is that lowering the axle 5 inches seems to have done the trick. I’d like a few more launches with a good surface but the prop wash didn’t disturb the wing prior to throttle up.

The landing was terrible. I descended a bit much before final and landed hard. No damage to man or machine. I’m glad there were no witnesses.

The GoPro Max didn’t record and the 11 Black didn’t stabilize…. So much for video.

Notes… yellow lenses for sunset launches. Raise the beaners on the kiting harness.

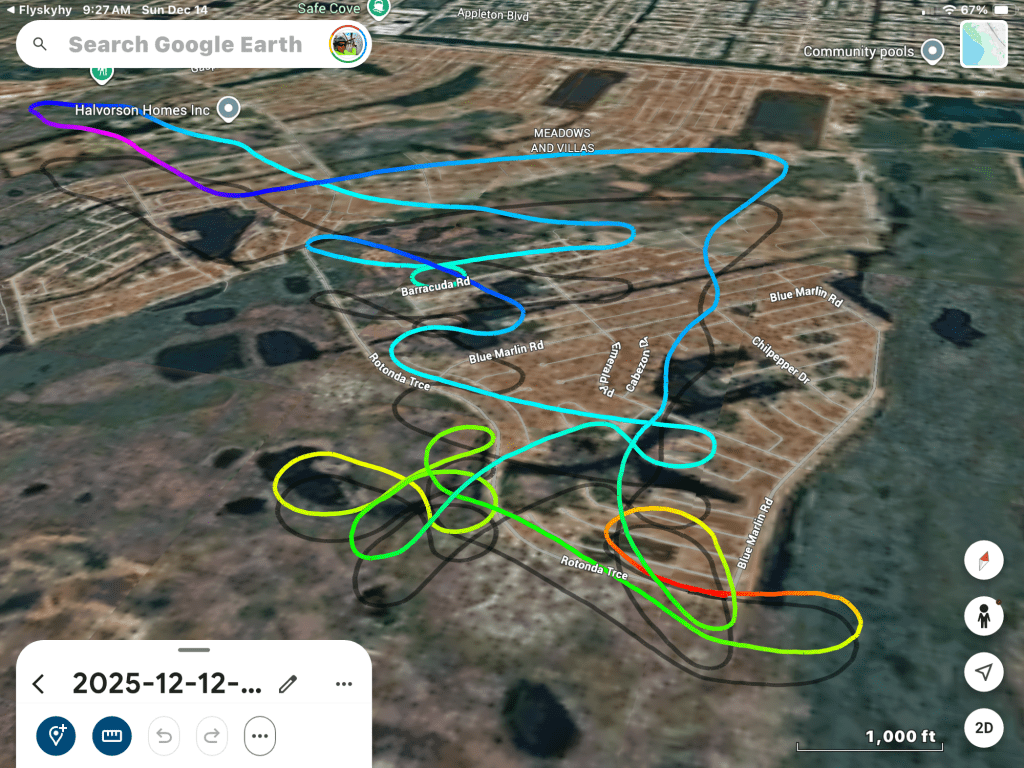

Good flight except that the wing wasn’t exactly centered and I had to make some fast and dramatic inputs to inflate and center the wing. I’m thinking the narrow opening in the nose of the glider make it easy for the prop wash to inflate one side or the other if not dead on centered.

I’m more convinced that the wash has to be raised to allow forward motion to start the inflation.

Good flight but the wing made a taco during inflation.

Next time I going to try a bit deeper V and tuck up the center to try to keep the prop wash from catching it.

Good Flight

Discovered damaged sheath of main D 3. MD3

You must be logged in to post a comment.